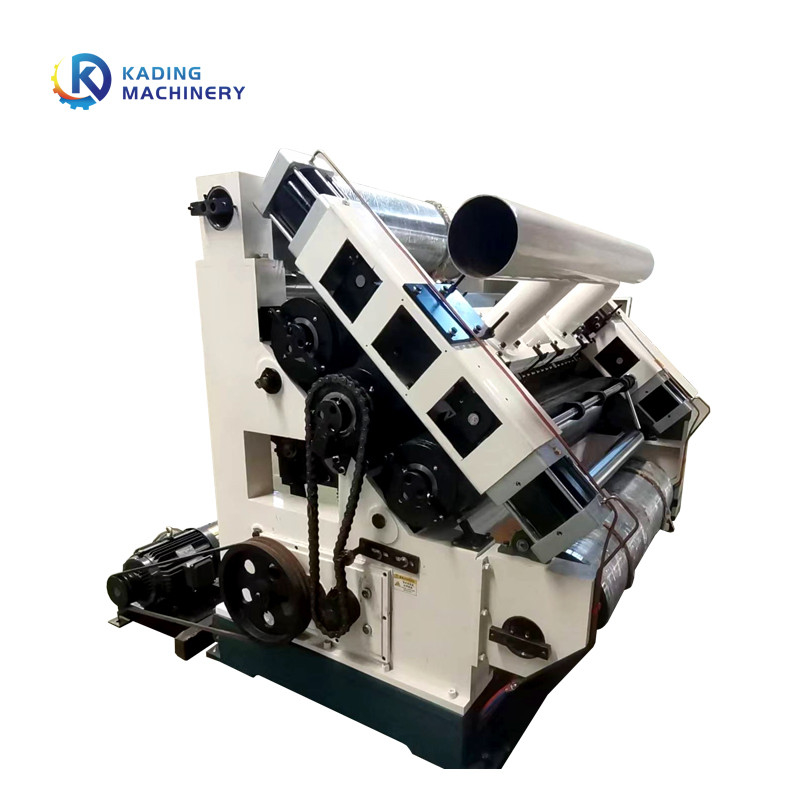

Steam heating Single Facer Corrugated Machine automatic Flute Forming Machine

The Steam Heating Single Facer Corrugated Machine Automatic Flute Forming Machine is an advanced piece of equipment designed for efficient and automated production in the corrugated packaging industry. This innovative machine combines the benefits of steam heating with a single facer corrugated design, enabling high-quality flute forming with enhanced speed and accuracy. In this introduction, we will explore the machine from three key aspects: functionality, features, and advantages.

Single Facer Machine Specification

| Working Width |

1200mm-2500mm |

| Heating Method |

Steam/Electric/Oil heating (optional) |

| Speed |

100m/min, 150m/min, 180m/min, 200m/min, 220m/min, 250m/min |

| Compress-Air Pressure |

0.4-0.9MPa |

| Flute Type |

Standard flute |

UV flute |

| |

Standard spec. |

A,B,C,E,F |

| Corrugated Roller Diameter |

φ280mm, φ320mm, φ360mm, φ380mm, φ405mm |

| Wall Thickness |

130mm |

| Type |

Fingerless/Cassette/Vacuum absorb |

*Machine's specification is subject to the final confirmation of seller and buyer.

Functionality

The Steam Heating Single Facer Corrugation Machine Automatic Flute Forming Machine excels in producing high-quality corrugated boards by efficiently converting paper rolls into fluted sheets. It incorporates a steam heating system that ensures consistent temperature control, enabling precise and uniform flute formation. The single facer design allows for a streamlined and continuous production process, eliminating the need for additional machines.

Features

1. Steam Heating System: The machine utilizes a state-of-the-art steam heating system, which offers superior heating efficiency and ensures optimal conditions for the formation of corrugated flutes. This system facilitates the quick and uniform heating of the paper, resulting in consistent flute profiles.

2. Single Facer Corrugated Design: The single facer mechanism simplifies the production process by combining the corrugation and bonding stages into a single operation. This design reduces the machine's footprint, saves energy, and improves overall efficiency. It also minimizes the handling and transportation of materials, leading to fewer operational bottlenecks and increased productivity.

3. Automatic Flute Forming: The machine is equipped with advanced automation features that streamline the flute forming process. It includes precision controls for adjusting flute height, flute type, and other critical parameters, ensuring accurate and customizable flute profiles. The automatic operation reduces manual intervention and enables higher production speeds, resulting in improved productivity and cost-effectiveness.

Advantages

1. Enhanced Efficiency: The integration of steam heating and single facer technology optimizes the machine's efficiency, allowing for faster production cycles and higher output. This results in reduced production costs and improved profitability for corrugated packaging manufacturers.

2. Superior Quality: The Steam Heating Single Facer Corrugated Machine Automatic Flute Forming Machine ensures consistent and precise flute formation, leading to high-quality corrugated boards. The automated controls minimize human errors, and the steam heating system guarantees uniform heating, producing reliable and durable flutes.

3. Cost Savings: By combining multiple production stages into a single machine, the Single Facer Corrugated Machine reduces capital investment and operational costs. The energy-efficient steam heating system reduces electricity consumption, while the automatic features minimize material waste and labor expenses. These cost savings contribute to the long-term sustainability of corrugated packaging businesses.

In conclusion, the Steam Heating Single Facer Corrugated Machine Automatic Flute Forming Machine offers advanced functionality, innovative features, and significant advantages. Its steam heating system, single facer design, and automatic flute forming capabilities enhance efficiency, ensure superior quality, and deliver cost savings to corrugated packaging manufacturers. With this machine, businesses can achieve streamlined production processes, higher output, and improved profitability in the competitive packaging industry.

Single Facer Machine Descriptions

The corrugated 48CRMO alloy steel is used, and the surface hardness of the heat treatment is above HV1200.

The corrugated roller module is separated from the entire machine, which can be replaced by the overall lifting and replace the ascent type at any time.

The adhesive and fixed paste are designed as a group guide track and disassembling to shorten the maintenance time.

The main transmission of the frequency conversion motor, the independent driver box, and the three -axis transmission, which controls the acceleration of the corrugated machine by the inverter, and achieves a communication interface to achieve energy -saving effects in the future.

Both the corrugation roller and pressure roller bearing are high -temperature lubricating fat to ensure long bearings and smooth operation.

The closed gear transmission oil is soaked, the noise is small, the operation is stable, and the life of the gear is long.

The host is suspended, and the glue area is rotated to avoid drying the roller surface.

Configure the spray device to adjust the humidity of the original paper at will.

The corrugated roller is made of special alloy steel of 48CRMO alloy steel, and the hardness is HRC58 ° -60 °

Oil lubricating gear box, low noise and universal transmission, and also separate power. Main motor conversion control (optional).

The vacuum suction system can provide a perfect flute shape even at high speeds, and the explosive volume controller is equipped.

The bearings of corrugated rollers and pressure rollers are lubricated by high temperature lubricating oil.

The surface of the bonding roller is carved and chrome -plated by special mesh patterns. Automatic and periodic glue of glue unit.

Cangzhou Kading Carton Machinery Manufacturing Co., Ltd's factory was founded in 2009 and is located

in Dongguang County, Cangzhou City, Hebei Province.

We are a manufacturing enterprise that produces carton making machinery, with 30 expereinced workers,

2 professional product tester, and 1 core skilled carton printer engineer; Besides, we also have a sales team

composed of a group of young people with forward thinking, we can make a professional product plan for you

according to your product needs.

Our company's self-produced product lines include carton printing machines, carton die-cutting machines,

and carton slotting machines; Our advantageous products include Carton stitching machines, Folder gluer

machines, Flute laminating machines, Single facer machines, etc.

If some related products you need are not produced by ourselves, with our mature product supply chain

system, we will also help you purchase products that satisfy you with the most competitive price and the

most guaranteed quality as the standard.

In addition to our own foreign trade business, our factory also cooperates with many trading companies,

so our products are exported to dozens of countries such as the Middle East, Africa, Southeast Asia, and

the European Union, and are well received by the majority.

There are also many brand&branded manufacturers among our customers, these factories are very relieved

to entrust the production of some products to us, which is enough to show that our quality and production

conditions are trustworthy.

Cooperate with us, benefit together!

Q: Are you a factory or a trading company?

A: We are a direct manufacturer that is located in Dongguang county, Cangzhou city. Welcome to visit our factory!

We can also have video call if you’d like an online factory tour.

Q: How do you ensure your quality?

A: 1. Trustworthy and long-term cooperative raw material suppliers;

2. Skilled&experienced engineer&workers;

3. Mature QC system;

4. Specially-assigned merchandiser;

5. Advanced production workshop.

Q: How about your after-sale service?

A: 1. Special after-sale team will be 24/7 online;

2. Can guide the installation door-to-door;

3. One-year warranty for spare parts.

Q: How many languages does your machine support?

A: Our machine supports all the languages.

Q: How long it will take to produce machine?

A: Delivery time largely depends on the machine type, for some small machine like manual stitching machine, manual

banding machine etc, usually we have stock available.

But for the large machines like carton printing die cutting machine, automatic stitching machine etc, it usually takes

around 35-50 days to produce.

Q: Can we visit your factory?

A: Sure, welcome to pay a visit for our factory, we will pick you up from airport, and will provide accommodation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!