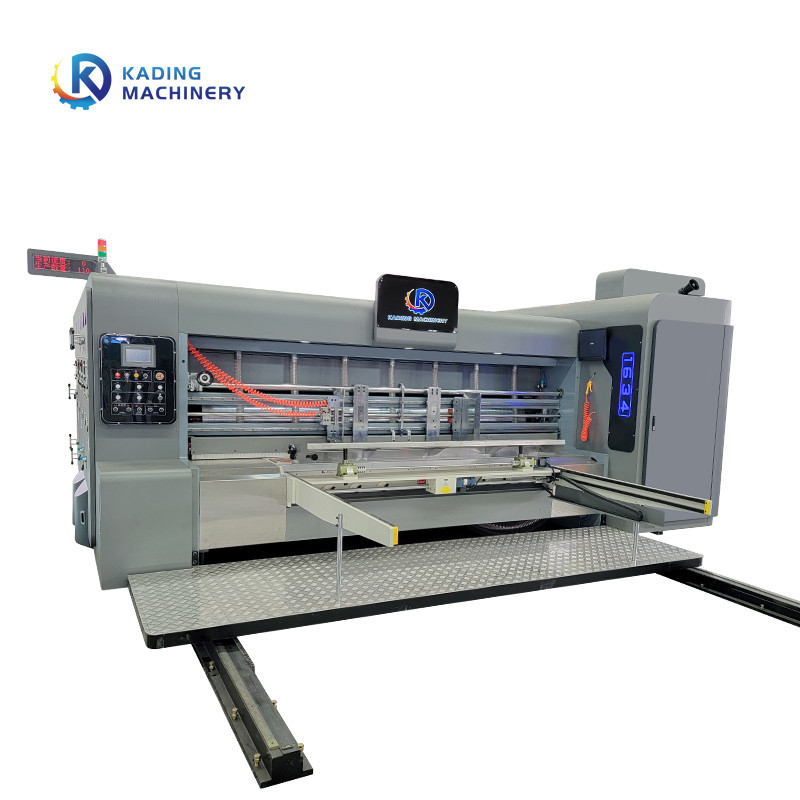

Servo Motor Feeding Corrugated Cardboard Printer With Rotary Slotting Die Cutter

All those who want to build a carton factory will probably experience similar problems. Where can I find the most suitable machine for me? Which machine can produce the corrugated boxes I need? Which machine is of good quality and durable? But don't worry, my friend, when you see this article, the above problems will be solved, because our corrugated cardboard printer can produce any kind of corrugated boxes, through various customized needs, it can definitely meet your order needs in all aspects!

Printing Slotting Die Cutting Machine Parameters

| Model |

KAF-1224 |

KAF-1228 |

KAF-1624 |

KAF-1628 |

KAF-1632 |

| Max.mechanical speed (pcs/min) |

180 |

180 |

160 |

160 |

160 |

| Max.feeding size (mm) |

1200*2600 |

1200*3000 |

1600*2600 |

1600*3000 |

1600*3400 |

| Min.feeding size (mm) |

720*340 |

720*340 |

720*420 |

720*420 |

720*420 |

| Skip feeding size (mm) |

1400*2600 |

1400*3000 |

1800*2600 |

1800*3000 |

1800*3400 |

| Valid printing area (mm) |

1200*2400 |

1200*2800 |

1600*2400 |

1600*2800 |

1600*3200 |

| Printing plate thickness (mm) |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

| Min.slotting space (Upper knife)(mm) |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

| Min.slotting space (Lower knife)(mm) |

260*70*260*70 |

260*70*260*70 |

260*70*260*70 |

260*70*260*70 |

260*70*260*70 |

| Max.slotting depth (mm) |

300 |

300 |

400 |

400 |

400 |

| *If need higher speed or other configuration, please ask our salesman for more details. |

The servo motor paper feeding of the corrugated cardboard printer is a kind of vacuum adsorption leading edge. Its working principle is to use the adsorption force generated by the compressor to make the paper firmly adsorbed on the lower end of the paper feeding leading edge, and then use the friction generated by the paper feeding wheel to feed the corrugated cardboard into the machine. Because the working principle of the vacuum adsorption leading edge is different from that of the ordinary leading edge paper feeding, there is no squeezing of the corrugated cardboard by the paper feeding wheel and paper feeding roller of the ordinary leading edge paper feeding, so there will be no damage to the corrugated cardboard due to squeezing. At the same time, the paper feeding speed and paper feeding accuracy will become higher, which will further improve the production efficiency and reduce the failure rate of the machine. There are many differences between ordinary leading edge feeding and vacuum leading edge feeding: the advantage of ordinary leading edge feeding is that it is a fully automatic paper feeding with low cost. Although the feeding speed is not as high as that of vacuum leading edge feeding, it is also very good and can meet most production needs. It is also a trustworthy choice for customers.

Rotary slotting die cutter is a common configuration of corrugated cardboard printer. Its feature is that one unit integrates two functions of slotting and die cutting. Generally speaking, the slotting part and the die cutting part are separate, which means that you need to buy two units to have two functions, which undoubtedly requires more machine cost and maintenance cost. However, rotary slotting die cutter can combine two functions into one. You can buy the functions of two units for the price of one unit. This is undoubtedly a very cost-effective choice. In fact, this is also a configuration we often recommend to customers.

Are you interested in our corrugated cardboard printer? Send us an inquiry!

Corrugated Box Printing Machine Picture

Q: Are you a factory or a trading company?

A: We are a direct manufacturer which is located in Dongguang county, Cangzhou city, we mainly manufacturing corugated carton box printing slotting die cutting machine, folding gluing stitching machine, single facer corrugated machine etc. Welcome to visit our factory!

We can also have video call if you’d like an online factory tour.

Q: How do you ensure your quality?

A: 1. Trustworthy and long-term cooperative raw material suppliers;

2. Skilled&experienced engineer&workers;

3. Mature QC system;

4. Specially-assigned merchandiser;

5. Advanced production workshop.

Q: How about your after-sale service?

A: 1. Special after-sale team will be 24/7 online;

2. Can guide the installation door-to-door;

3. One-year warranty for spare parts.

Q: How many languages does your machine support?

A: Our machine supports all the languages.

Q: How long it will take to produce machine?

A: Delivery time largely depends on the machine type, for some small machine like manual stitching machine, manual

banding machine etc, usually we have stock available.

But for the large machines like carton printing die cutting machine, automatic stitching machine etc, it usually takes

around 35-50 days to produce.

Q: Can we visit your factory?

A: Sure, welcome to pay a visit for our factory, we will pick you up from airport, and will provide accommodation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!